How ITSM Powers Manufacturing Success

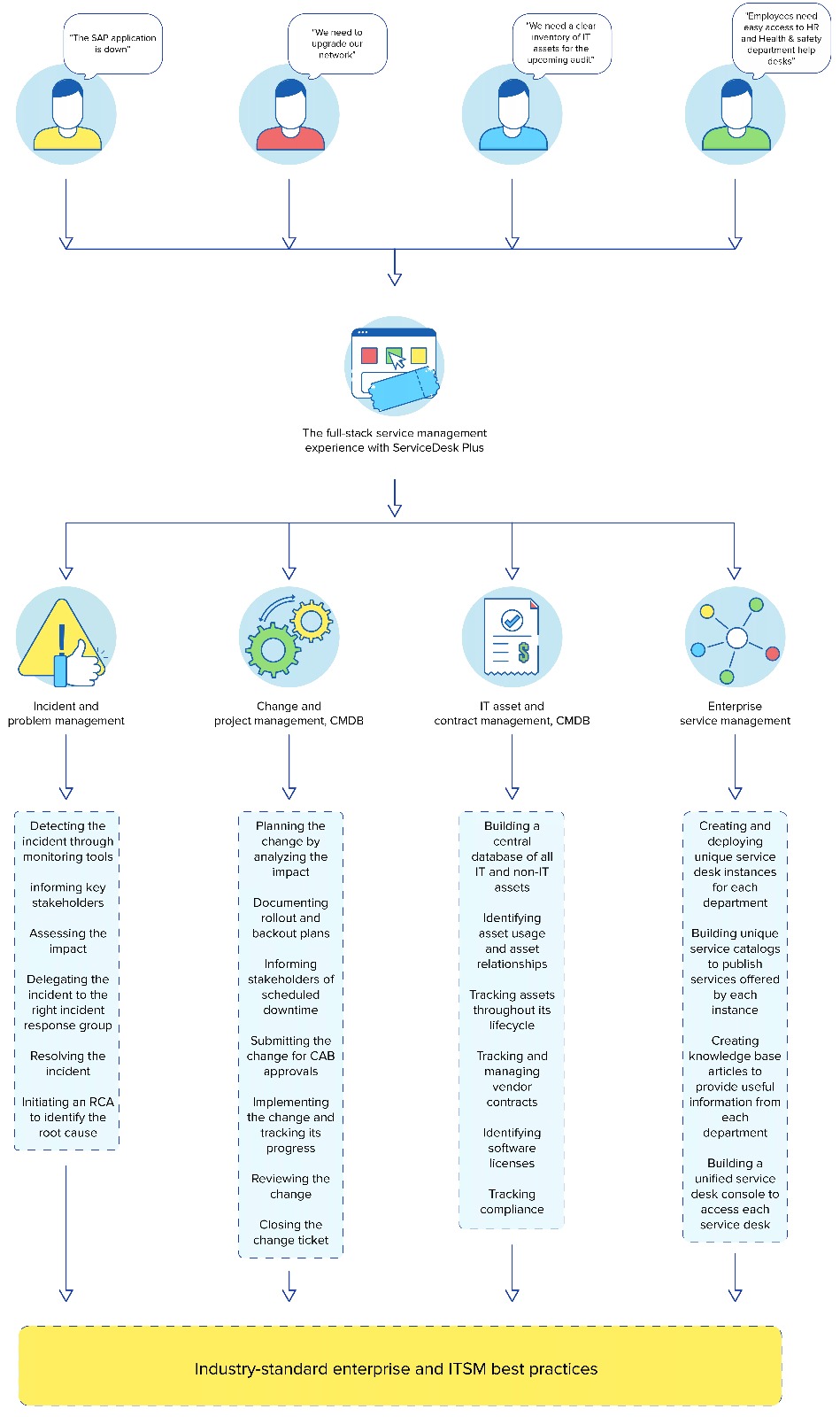

In manufacturing, every second of uptime counts. An effective ITSM strategy ensures critical systems — from production lines to supply chain operations — run seamlessly, while also improving the user experience for employees on the floor and in back offices. With KEDAR’s full-stack ITSM platform, manufacturers can streamline core functions, resolve issues faster, and build a resilient IT backbone that supports efficiency, innovation, and measurable business gains

The Role of ITSM in Modern Manufacturing

The manufacturing industry has undergone a rapid digital transformation in recent years. Propelled by Industry 4.0 and the rise of Industry 5.0, manufacturers are moving beyond outdated, siloed systems toward smart, connected environments that leverage IoT, AI, machine learning, and big data. These advances have unlocked new efficiencies in production, but they also place unprecedented demands on IT infrastructure.

Smart equipment and connected systems now monitor machine health, proactively flag anomalies, and feed into enterprise IT. This means IT is no longer just a support function it is a core enabler of manufacturing success. Downtime in IT systems can halt production lines, disrupt supply chains, and impact customer relationships. To remain competitive, manufacturers must establish a solid IT Service Management (ITSM) strategy that ensures stability, resiliency, and efficiency.

With KEDAR, manufacturers gain a full-stack ITSM platform designed to unify people, processes, and technology, creating a structured foundation to manage IT operations. This empowers IT teams to deliver consistent service, improve user experiences, and minimize downtime directly translating to higher productivity and stronger margins in an increasingly competitive market.

Key ITSM Challenges for Manufacturers

Disorganized ITSM Operations

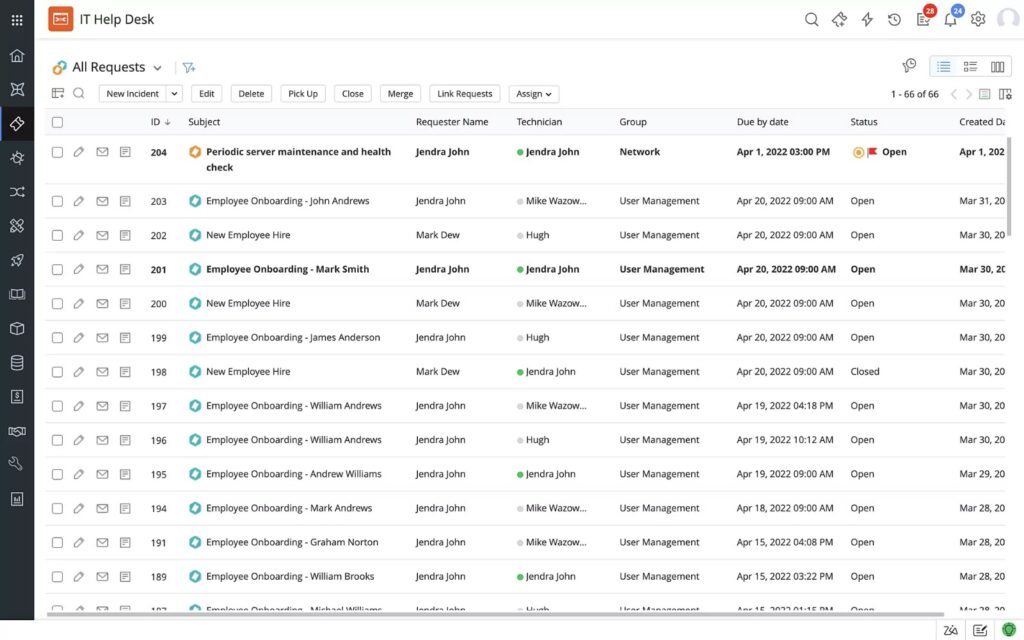

Many manufacturers attempt to manage IT with little more than a ticketing system, but this approach falls short. Without adopting core ITSM practices, IT teams struggle to respond quickly to incidents, track problems to their root cause, and deliver services on time. The lack of structured workflows increases overhead and erodes efficiency. A strong ITSM solution like KEDAR overhauls operations by providing:

• Faster incident resolution to reduce downtime.

• Root cause analysis (RCA) for recurring issues.

• A centralized service catalog to standardize employee support.

• Asset management to optimize IT spending

Poor User Experience

While factories adopt smart machinery, employees, vendors, and customers are often left with outdated IT support systems. Inefficient service delivery for employees slows internal productivity, while weak communication with suppliers or customers damages relationships.

KEDAR provides a unified access point for every user group:

• Employees can easily request workstation fixes, HR support, or time-off applications.

• Vendors and suppliers can track purchase orders, flag product issues, or initiate recalls.

• Customers can log warranty claims, request spare parts, or seek product support.

This streamlined service delivery boosts satisfaction and helps align IT support with overall manufacturing goals.

Lack of Automation

Manufacturers continuously seek automation on the factory floor yet many neglect IT automation, leading to wasted time and higher costs. Without it, technicians must manually handle repetitive tasks like assigning tickets, sending notifications, or escalating issues.

With KEDAR, manufacturers can:

• Automatically assign tickets based on rules.

• Trigger workflows for standard requests.

• Accelerate resolution times and reduce technician workload.

By automating ITSM operations, manufacturers improve margins by reducing downtime and freeing teams to focus on critical, high-value activities.

Insufficient Data for Decision-Making

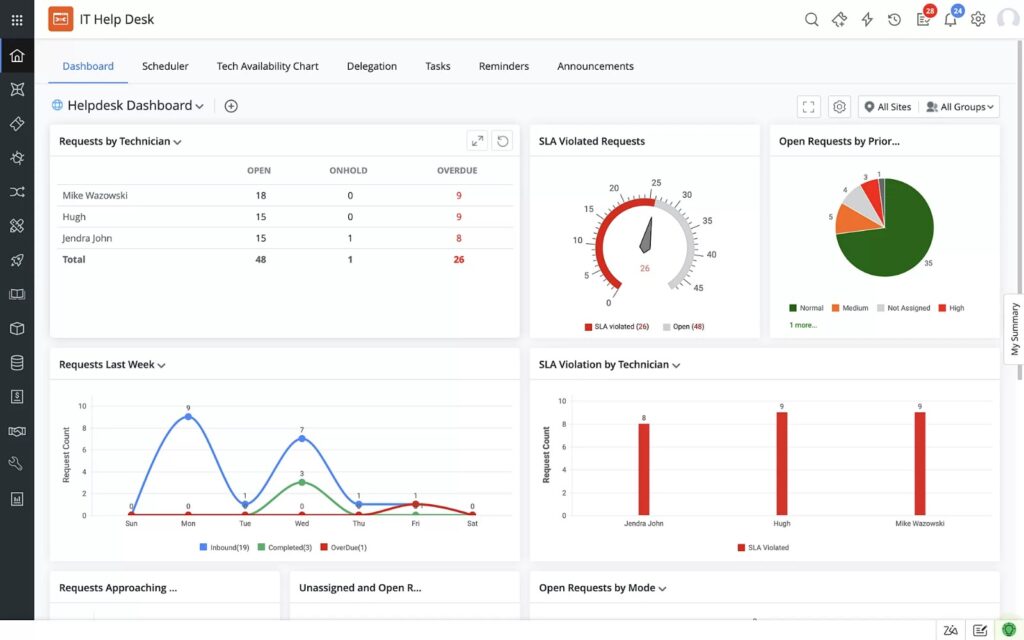

Manufacturers thrive on precision, but many lack organized ITSM data to make informed operational decisions. Without strong reporting, IT teams cannot assess workloads, optimize asset use, or identify inefficiencies.

KEDAR’s advanced analytics provide:

• Real-time dashboards with service desk KPIs.

• Insights into technician performance and resource needs.

• Data to realign ITSM processes with business goals.

This empowers leadership to make smarter, faster decisions that support business growth.

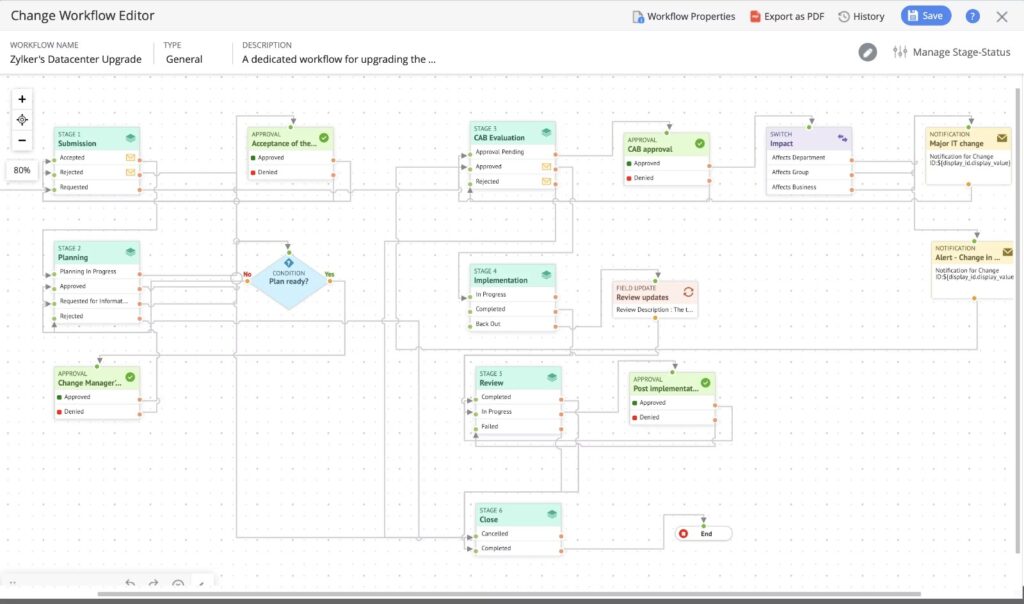

Adopting New Technology Safely

To stay ahead, manufacturers must continually upgrade or adopt new technologies. However, poorly managed IT changes can introduce risks, disrupt operations, or compromise other systems.

KEDAR’s change management and CMDB offer:

• A bird’s-eye view of the IT infrastructure.

• Controlled change deployment with clear impact assessments.

• Structured approvals with change advisory boards.

This ensures upgrades strengthen, rather than destabilize, manufacturing IT environments.

The KEDAR Advantage for Manufacturers

Unlike standalone ticketing systems, KEDAR delivers a full-stack ITSM experience tailored to manufacturing. From consolidating IT data to automating workflows, it helps manufacturers streamline both IT and non-IT processes. With out-of-the-box best practices, seamless integrations, and scalable modules, KEDAR transforms IT into a true enabler of manufacturing success.

Manufacturers can:

• Streamline internal support with multi-channel incident reporting and proactive monitoring integrations.

• Accelerate response times using request life cycles, SLA-driven escalations, and preventive maintenance scheduling.

• Perform RCA to eliminate recurring issues and strengthen infrastructure reliability.

• Enable high-velocity service delivery across plants, suppliers, and customer support.

Establishing an ITSM Strategy with KEDAR

Modern manufacturing requires an ITSM approach that goes beyond ticketing to cover the entire spectrum of IT operations. With KEDAR, manufacturers gain a resilient IT foundation that:

• Reduces downtime with faster, smarter incident response.

• Standardizes IT services for employees, vendors, and customers.

• Unlocks insights through advanced reporting and analytics.

• Safely adopts new technologies with structured change management.

• Aligns IT and business goals to deliver consistent value across the enterprise.

In an industry where every minute counts, KEDAR provides the tools to keep production efficient, employees productive, and customers loyal — driving measurable gains for manufacturers competing in the era of Industry 4.0 and beyond.

Incorporate New Technology with Ease Using Changes and Projects

Adopt an eight-stage change management process to plan and implement upgrades with minimal risk.

• Automate workflows at every stage, including approvals, notifications, and field updates.

• Design visual change workflows on a drag-and-drop canvas for minor, major, and emergency changes.

• Use project management tools to implement large-scale technology changes efficiently.

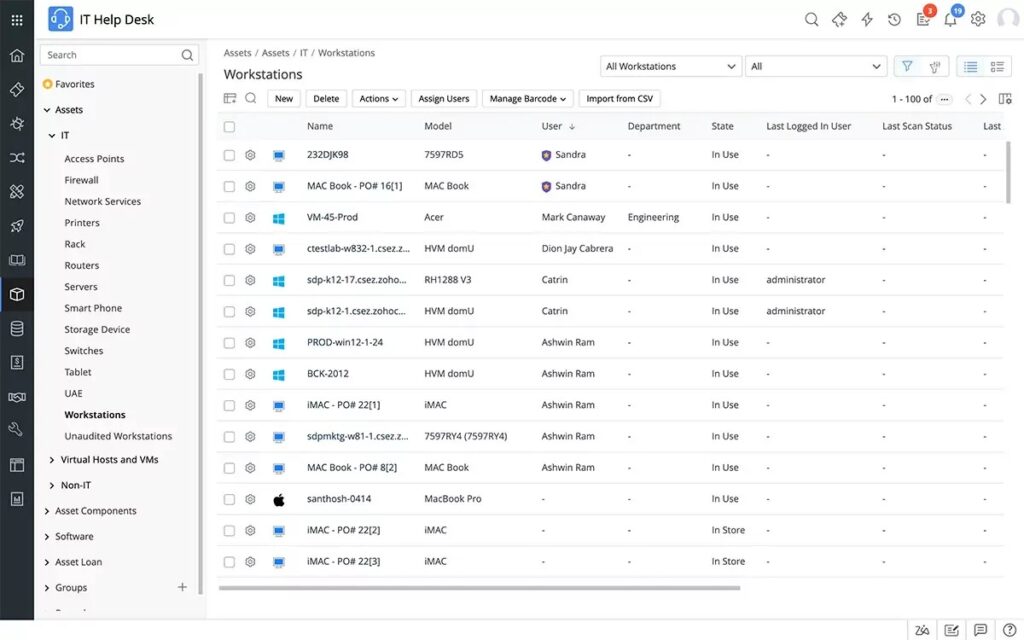

Implement a Robust ITAM Strategy for IT and Non-IT Assets

• Discover and scan all assets across sites, consolidating data into a single source of truth.

• Map services and asset relationships in a CMDB for deeper visibility.

• Optimize asset usage and configure depreciation rates to track value over time.

• Identify problem assets by linking incidents to recurring equipment failures.

• Stay audit-ready with real-time dashboards that track compliance status.

Harness ITSM Metrics to Drive Manufacturing Efficiency

• Access 180+ out-of-the-box reports for insights into ITSM performance.

• Build custom reports to track downtime, maintenance costs, and incident trends.

• Schedule automated reports to keep stakeholders aligned.

• Visualize real-time data with graphical dashboards and widgets for better decision-making.